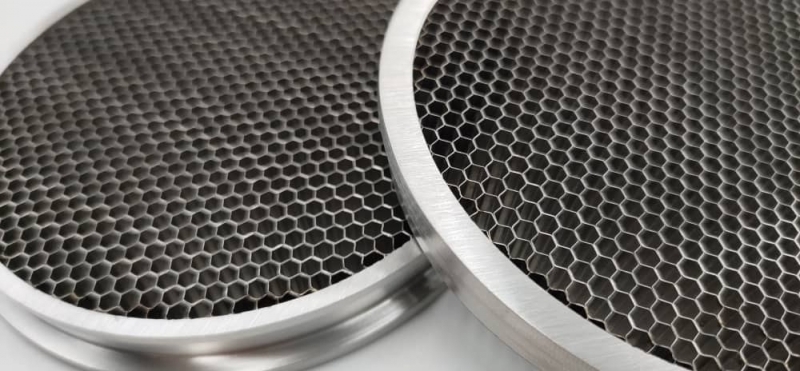

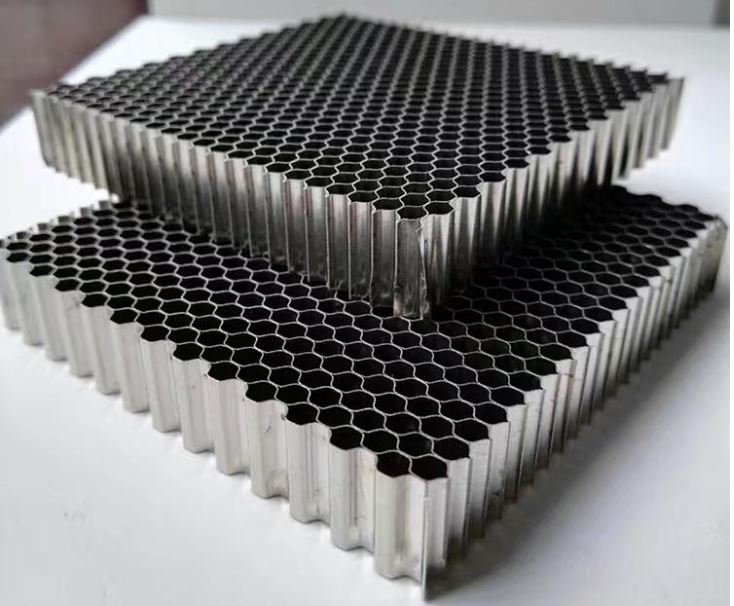

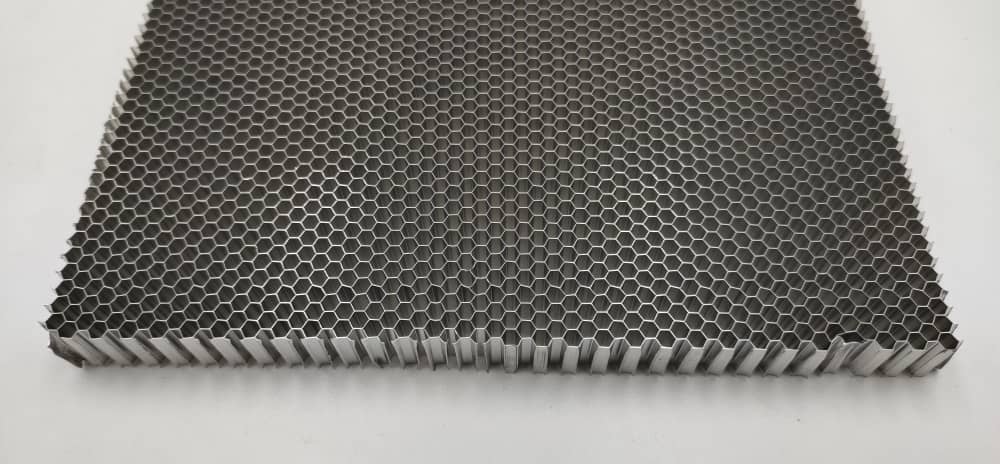

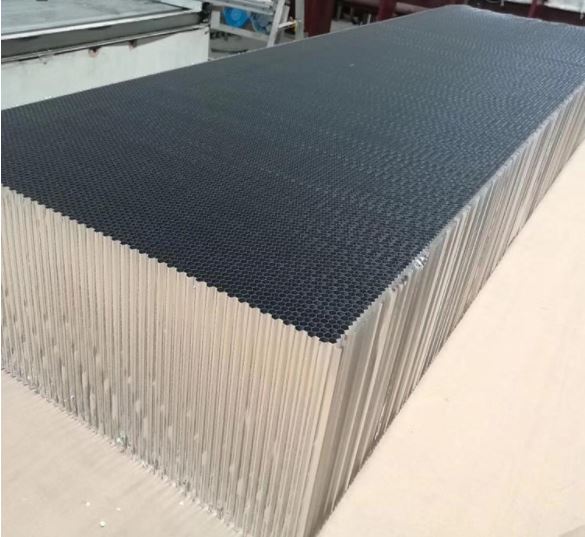

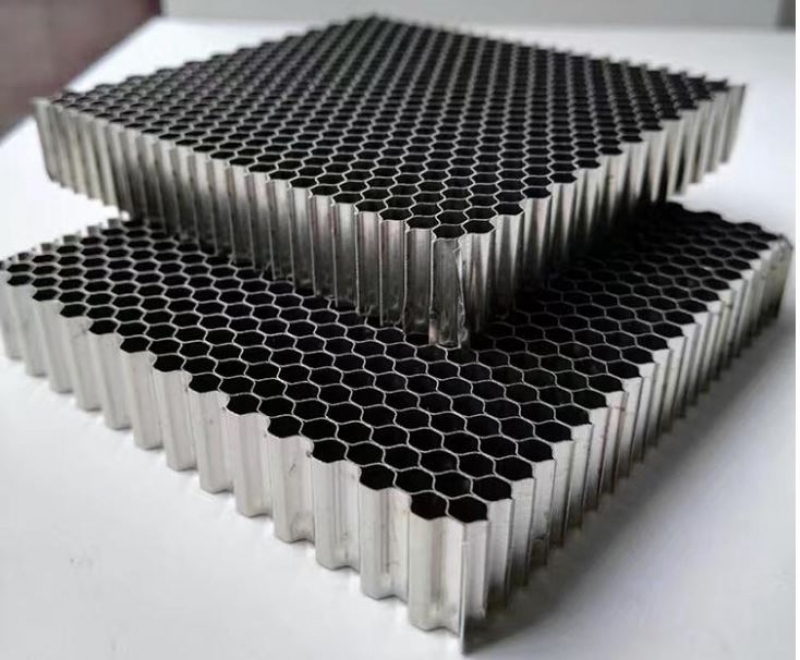

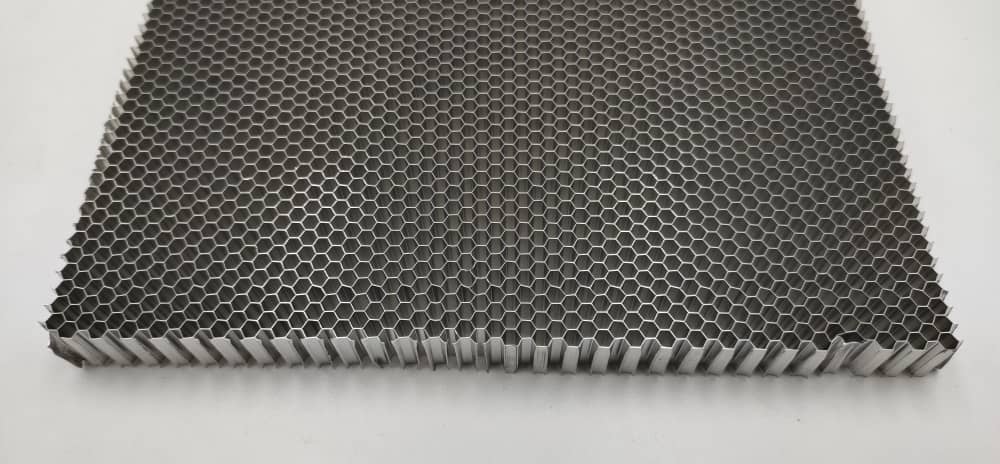

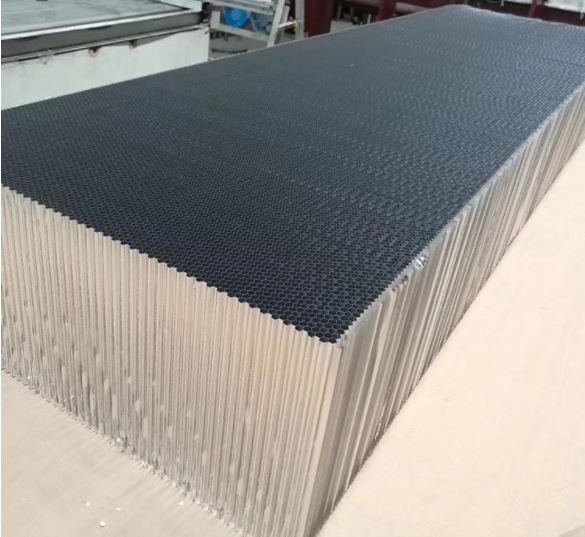

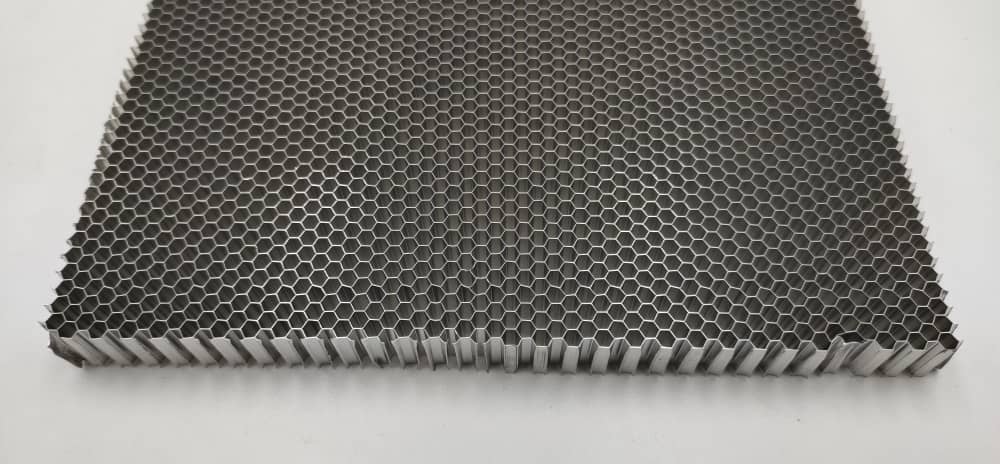

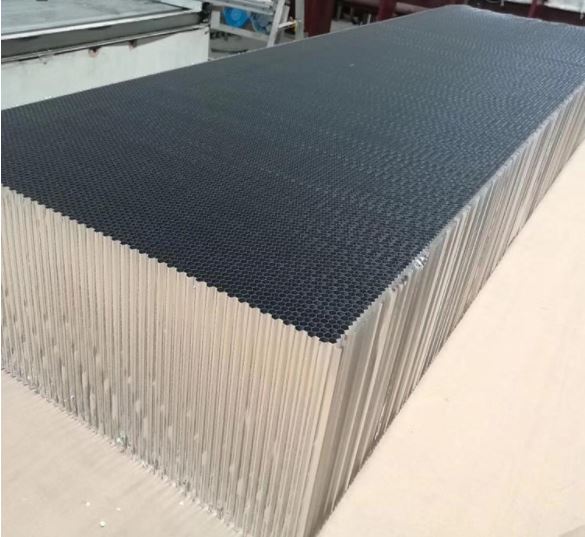

Aluminum Honeycomb Core

At the very beginning, aluminum honeycomb materials were mostly used in the aerospace and military sector. Aluminum Honeycomb panel has excellent strength and great performance in high wind pressure resistance, shock absorption, sound insulation, heat preservation, fire resistance, and high strength. Aluminum honeycomb grid core can also be used as an energy absorber and grids in front of spotlights and photographic equipment.

DMC aluminum honeycomb cores are made of 3003 or 5052 aluminum alloy foil.

- Excellent Strength

- Highly durable

- Lightweight

- Low cost

DMC aluminum honeycomb core is available based on the below condition:

- Minimum Core Thickness: 3 mm

- Minimum Cell Size: 2 mm

- Foil Thickness: 0.036 mm-0.18 mm

- Standard Dimension: 1220*2440mm

- Max. Expanded Size: 1600*20000 mm

Available in Various Categories:

- Block

- Unexpanded slices

- Expanded sheets

- Perforated or Non-perforated

- Drilled core

Mechanical Properties Of Aluminum Honeycomb Core

.png)

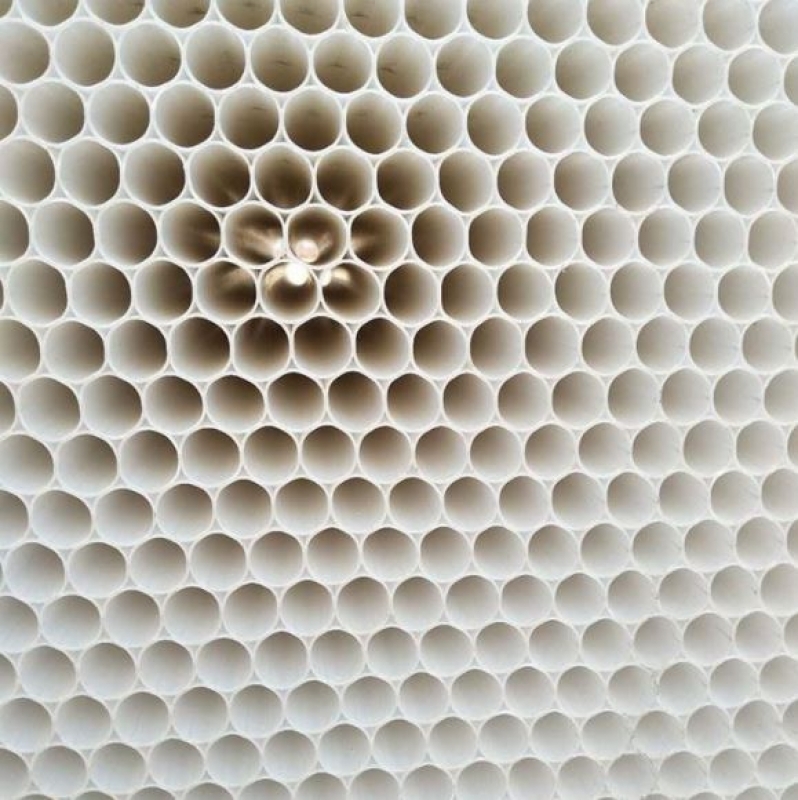

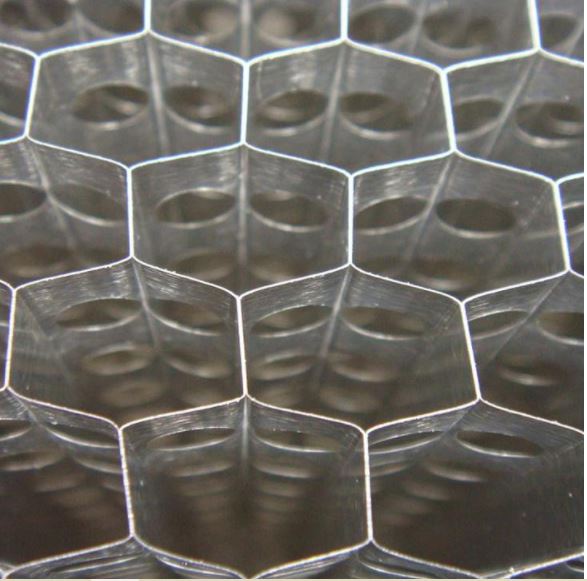

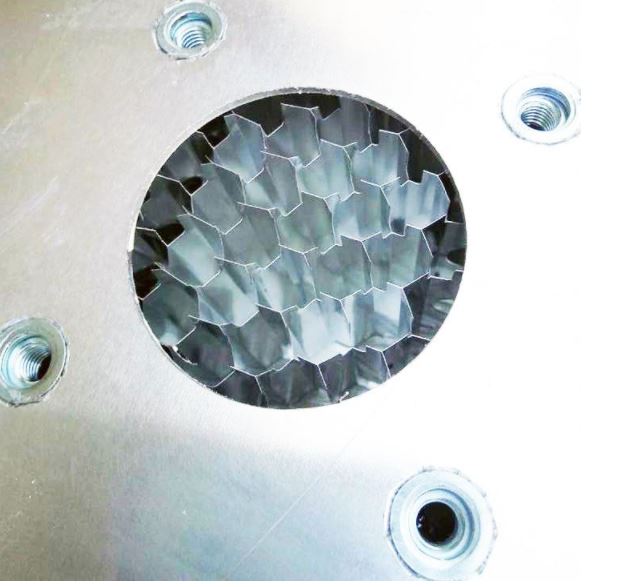

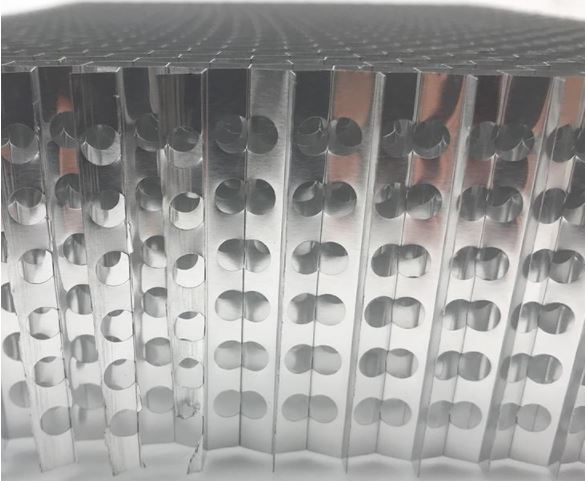

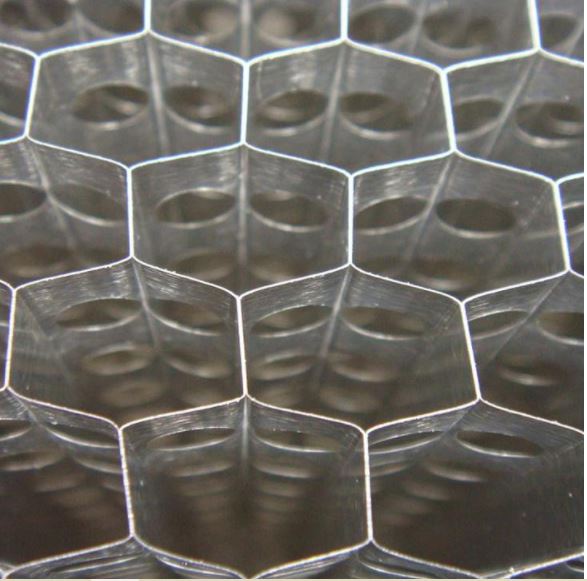

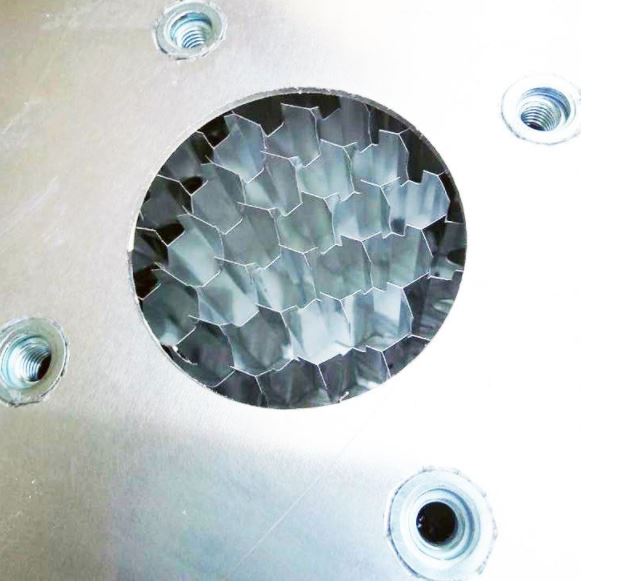

Drilled Aluminum Honeycomb

The vented aluminum honeycomb core is a drilled core material that perforated in the cell walls of the core at equal distance. With these perforated holes, drilled aluminum honeycomb core permits the correct airflow.

Normally, the drilled core can be used as core material for vacuum tables and for molds in the wind blade industry.

DMC drilled honeycomb core are available in the below configuration:

- Aluminum Alloy Grade: 3003, 5052

- Cell Size: 9.53mm, 12.64mm, 19.1mm

- Number Of Holes: 3 or 6 holes at direction T (equal distance)

- Drilling Hole Diameter: 3mm-5mm

- Core Thickness: 15mm-60mm

- It can be customized according to customer requirements

Drilled Core Technical Properties

.png)

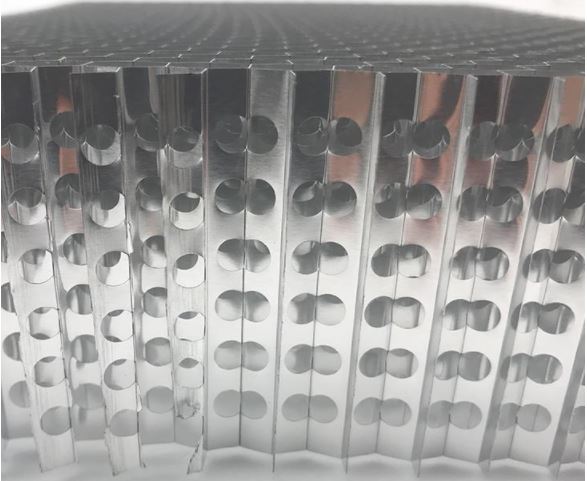

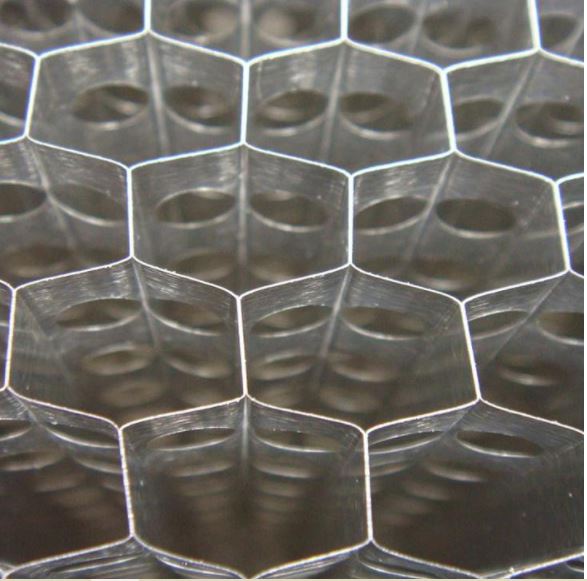

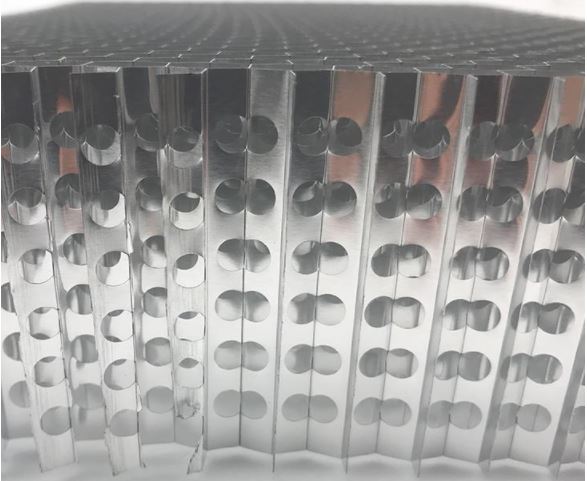

Vented Aluminum Honeycomb Core

Drilled aluminum honeycomb core can be used for air flow control, heat conduction, mold cooling, and energy absorption applications, such as vacuum table, anti-collision of protection guardrail, and molds in the wind blade industry. It’s a new aluminum honeycomb core which is stronger, more stable, lighter and has better air circulation properties. There are perforated holes in the equal distance on the drilled core walls.

DMC vented honeycomb core is available based on the below configuration:

- Aluminum Alloy Grade: 3003, 5052;

- Cell Size: 9.53mm, 12.64mm, 19.1mm;

- Number Of Holes: 3 or 6 holes at direction T (equal distance);

- Drilling Hole Diameter: 3mm-5mm;

- Thickness: 15mm-60mm;

It can be customized according to customer requirements.

Drilled Core Technical Properties

.png)

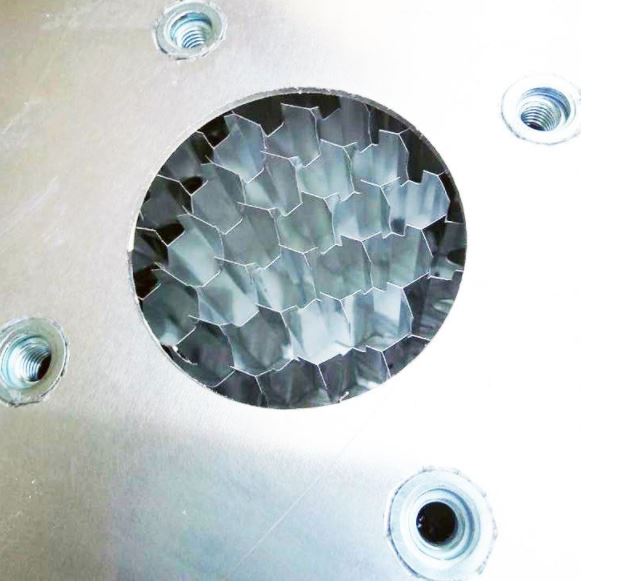

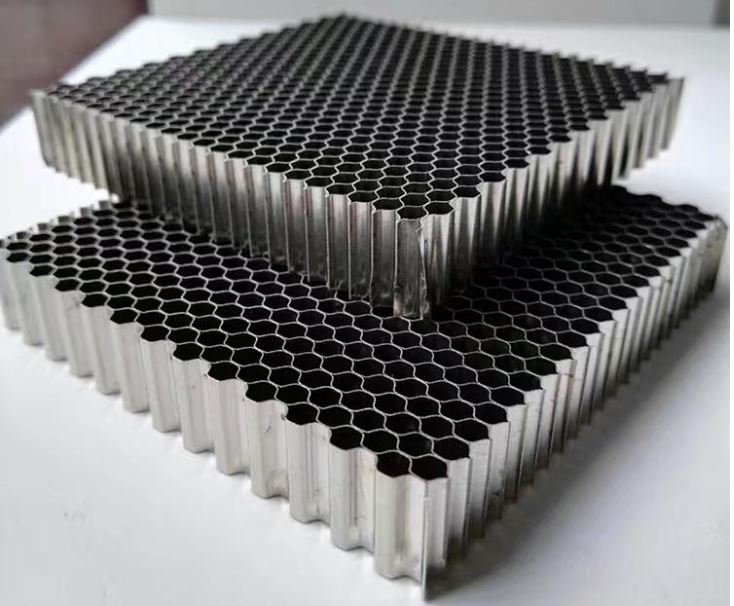

Perforated Honeycomb Core

DMC can produce a new aluminum honeycomb core which is stronger, more stable, lighter and has better air circulation properties, It has drilling holes in equal distance on the walls of the core, Air flow through core walls correctly to heat or cool a panel uniformly by these perforated holes. Normally, drilled aluminum honeycomb core is used as core for vacuum tables and for molds in the wind blade industry.

DMC can produce:

- Aluminum Alloy Grade: 3003, 5052;

- Cell Size: 9.53mm, 12.64mm, 19.1mm;

- Number Of Holes: 3 or 6 holes at direction T (equal distance);

- Drilling Hole Diameter: 3mm-5mm;

- Core Thickness: 15mm-60mm;

It can be customized according to customer requirements.

Drilled Core Technical Properties

.png)

.png)

.png)

.png)

.png)